(PCBA上的贴片晶振)

晶振厂家晶诺威科技关于晶振使用说明和焊接注意事项建议(中英文版)

晶振使用说明

Processing Instructions

以下说明和信息供用户正确理解和使用我们公司的晶振系列产品,预防不当的加工方式对晶振的损坏,确保用户设备的可靠性。The following instructions and information are provided for the purpose of having the user understand the proper way to process our crystal products to prevent problems prior to use and enhance the reliability of the equipment to which they are applied.

晶振使用指导

PROCESSING INSTRUCTIONS

晶振意外跌落When dropped by mistake

设计和制造的晶振本身具有耐冲击能力,但是当晶振组件经受剧烈的机械冲击,如跌落到地板上或安装期间剧烈震动时,在使用之前需要进行电性能确认。The crystal units are designed and manufactured to resist physical shocks.However,when the crystal units are subjected to excessive impact such as being dropped onto the floor or giving shocks during processing, need to make sure its satisfactory performance before using it.

晶振焊接注意事项

Soldering

- 引线型产品Lead Type products

- 焊接部位仅局限于导脚来到玻璃纤部位1.0 mm以上的部位,并且请不要对外壳进行焊接。另外,假如利用高温或长时间对导脚部位进行加热,会招致晶振特征的恶化以及晶振的破损。因此,请留意对导脚部位的加热温度要控制在300°C以下,且加热时间要控制在5秒以内(外壳的部位的加热温度要掌握在150°C以下)。The soldering area should be strictly limited to 1.0 mm above the glass fiber area of the leads and do not solder the metal cover. In addition, heating the leads’ area over time or over temperature might cause damage to the crystal unit. The caution is that more attention should be paid when the leads’ area is being heated: the temperature of processing should be controlled below 300 ℃,and the time with in 5 second. (The heating temperature around the cover area should be below 150℃)

- 使用浸锡方式焊接时,引线应该在10秒内焊接完毕,焊锡温度不能高于260℃,并且注意不能将整个晶振浸锡.推荐使用垂直安装方式,避免热力直接传导到晶振上。In solder-dip processing, the leads should be soldered within 10 seconds with a temperature no higher than 260℃.Mounting in upright is recommendable to prevent the heat conduction directly to the body of the crystal unit.

- SMD产品 SMD Type products

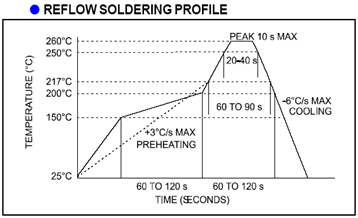

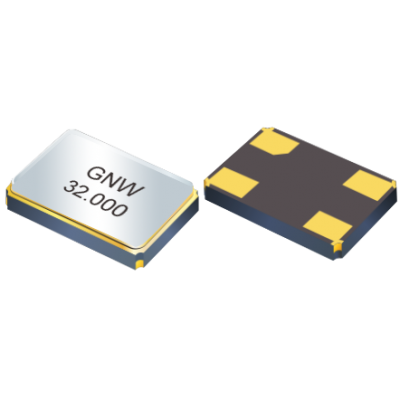

1、TMXLF-308F、TMXLF-AT206F/308F/309F/3010F、TMXLF-309产品系列推荐使用下面的回流焊曲线

The REFLOW SOLDERING PROFILE as below is recommended for TMXLF-308F、TMXLF-AT206T/308F/309F/3010F、TMXLF-309 family.

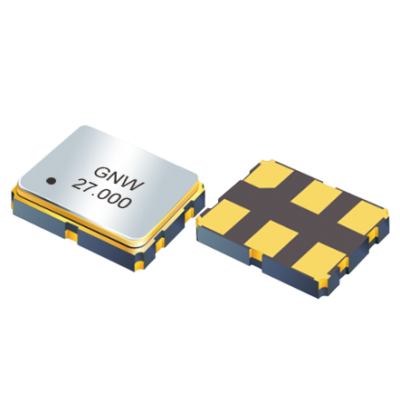

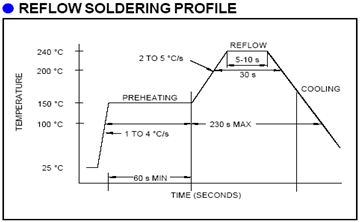

2、TMXLF-206/206F/206FA02、HC-49SMD产品系列推荐使用下面的回流焊曲线

The REFLOW SOLDERING PROFILE as below is recommended for TMXLF-206/206F/206FA02、HC-49SMD