(32.768KHz晶振8038/MC-306产品图)

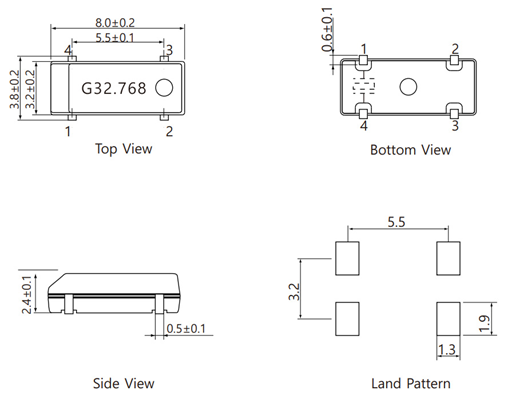

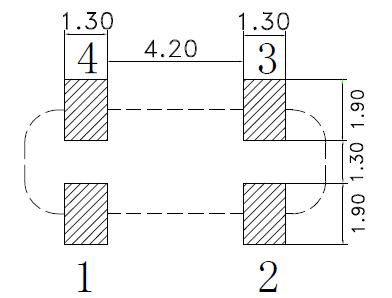

32.768KHz石英晶体谐振器 8038/MC-306尺寸及焊盘说明如下:

脚1与脚4为频率管脚;请不要连接脚2和脚3至任何应用电路。

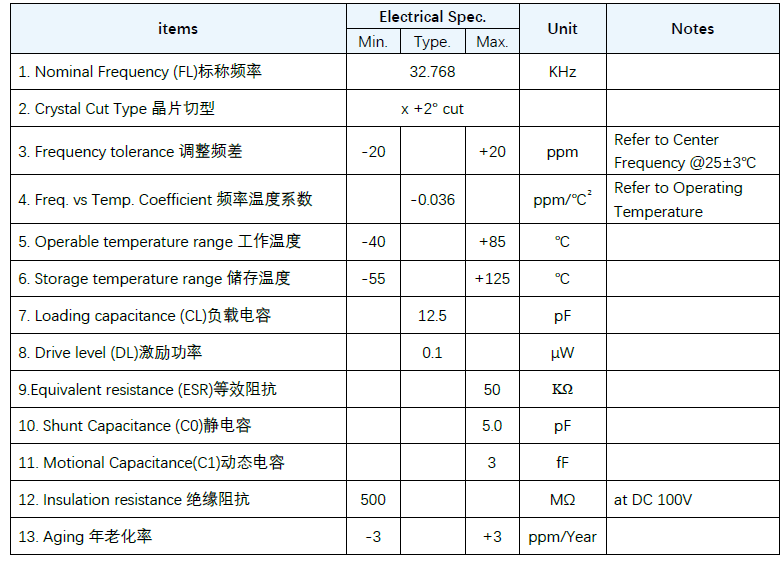

关于晶诺威科技产32.768KHz石英晶体谐振器 8038(MC-306)规格参数,介绍如下:

8038贴片陶瓷晶振MC-306 频率范围:32.768KHz 频差:±20PPM 老化:±3PPM/年 温度范围:-40~+85℃ 负载电容:12.5PF 体积:8.0*3.8*2.54mm 应用:Clock and Microcomputer,通信设备、GPS、计量仪表、工程机械、工业控制系统等。

Handling Notice for Standard Tuning Fork Crystal (Cylindrical Type)标准音叉类晶振注意事项

1、 Shock resistance 跌落

- It may deteriorate the characteristics or cause no oscillation if excessive physical shock occurs. Please be careful not to drop. Minimize any shock as much as possible.

请不要跌落本产品,晶体受到冲击可能会使之性能恶化或不起振。在使用时,请尽量避免震动。

- Please verify when it is soldered by auto mounting or if any working condition is changed.

请在使用自动焊接设备,或在工作环境改变的情况下,检测本品的性能。

2、 Heat and humidity resistance in storage 储存中得耐湿热性

- A storage of the crystal products under higher or lower temperature or high humidity for a long period may deteriorate the characteristics of crystal units.

长时间储存在高温,低温或高湿的环境下会使本品性能恶化。

- Please store the crystal products at the normal temperature and humidity.

请储存在常温常湿的环境中。

3、 Solder heat resistance 焊锡耐热性

- Please review the condition or consult us about flow solder process.

请查阅有关流动焊接工艺的条件或咨询我们。

- Our soldering condition is under 265ºC within 15±5sec

我们的焊接条件为低于265ºC 时间10~15 秒。

Mounting method to PCB (PCB 上的焊接方法)

1、 Recommended layout as shown below.

推荐焊盘尺寸如下图;

2、 Ultrasonic cleaning and/or ultrasonic soldering 超声波清洗和超声波焊接

Soldered and/or cleaned by ultrasonic cannot be guaranteed, because crystal may be damaged due to sympathetic vibration. Please verify before ultrasonic soldering and/or cleaning.

超声波焊接无法提供品质保证,因为晶体可能会发生共振,并可能损坏。若使用超声波工艺,请在使用前充分验证其对晶体的安全性。

3、 Drive level 激励功率

Applying excessive drive level to the crystal units may cause deterioration of characteristics or fatal damage. Less than 1.0μW is recommended to this product. Over 2.0μW cannot be guaranteed.

对晶体施加较大的激励功率会导致晶体的性能恶化或者损坏。我司推荐晶体激励功率小于1.0μW,超过2.0μW 激励功率我司无法保证晶体品质稳定。

4、Solder paste should be more than 150μm thickness.

焊膏厚度应不低于150μm。

5、 Storage environment 储存环境

- Store at +15℃ to +35℃,25%RH to 65%RH of Humidity.

请在温度+15℃~+35℃,湿度25%Rh~65%Rh 的环境下储存物料。

- Do not expose to the sunlight directly.

请勿暴晒

- Do not store with erosive chemicals.

请勿与腐蚀化学物质储存在一起。

- Do not put anything on the crystal units or cartons to prevent any possible mechanical damage.

为了防止机械损坏,禁止将任何东西放在料盘或纸箱上。