(+125度高温车规级晶振32.768KHz规格参数)

关于+125度高温车规级晶振32.768KHz规格参数,晶诺威科技介绍如下:

Application 应用领域

Automotive equipment 汽车设备

Features 性能及特点

- Compact, thin, and light weight tuning fork crystal unit 小体积、音叉晶体

- Load Capacitance 负载电容:6pF,9pF,12.5pF或定制

- Excellent heat resistance and environmental resistance performance 优异的耐热性和耐环境性

- Reflow temperature profile (Available for lead free soldering)适合回流焊作业(适用于无铅焊接)

- Conforms to AEC-Q200 符合车规AEC-Q200

Mounted conditions 安装条件

Be sure to use the product under the following conditions. Otherwise, the characteristics deterioration or destruction of the product may result. 请务必在以下条件下使用该产品,否则可能导致晶振特性受损或失效。

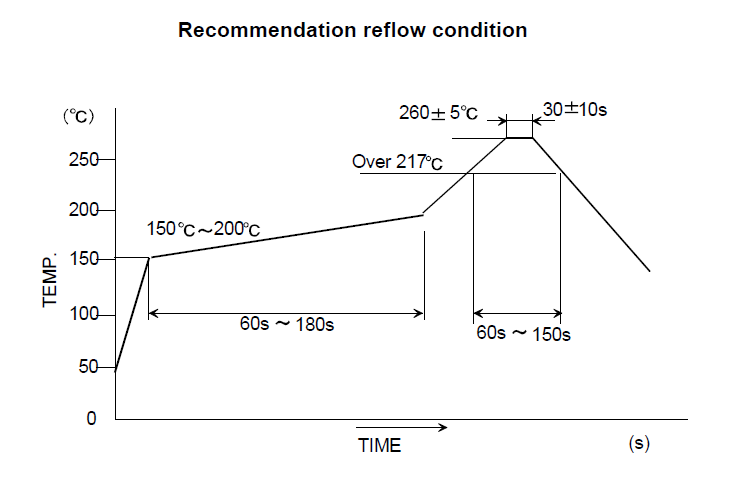

(1) Reflow soldering heat resistance回流焊耐热性

Peak Temp. 峰值温度:+260℃, 40 sec.

Heating 加热:+217℃ or higher, 150 sec.

Preheating 预热:+150~+200℃, 180 sec.

Reflow passage times回流焊次数 :twice 两次

(2) Manual soldering heat resistance手焊耐热性

Pressing a soldering iron of 400°C on the terminal electrode for four seconds (twice).

将400°C的烙铁压在晶振焊盘(电极),持续时间四秒钟(次数两次)。

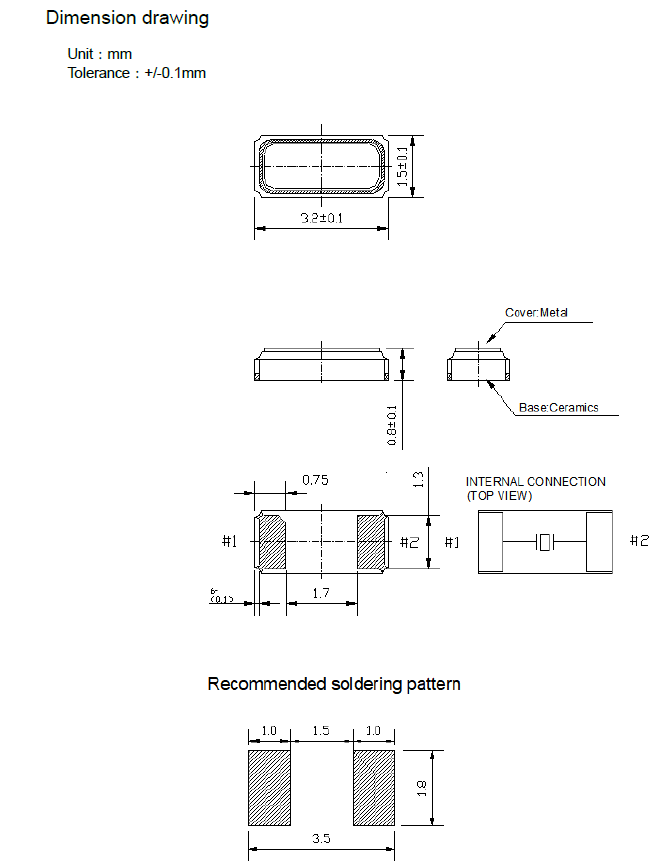

Dimension and recommended soldering pattern 尺寸及焊盘说明:

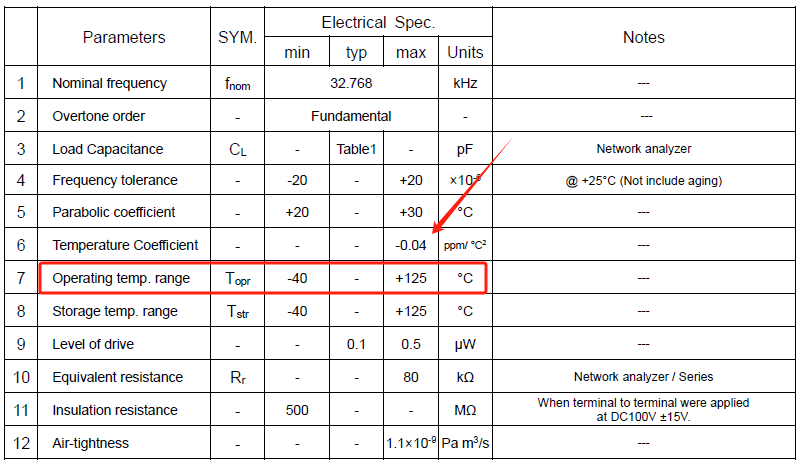

注:该系列32.768KHz车规级晶振优势主要体现在以下四方面:

1、工作温度由工业级+85℃提高到车规级的+125℃,满足汽车级温度使用需求,是一款真正的耐高温晶振;

2、频率温度系数仅为-0.04ppm/℃,输出频率受温度的影响较小,可提供稳定的32.768kHz的输出频率;

3、晶振表面材料由玻璃(GLASS)升级为全金属,在抗恶劣工作环境方面有了提升;

4、驱动功率(Drive Level)仅为0.1uW,可满足汽车低功耗的应用需求。